Products

Single Port Quick Exhaust Valve P41X-10Q

The single-port quick exhaust valve P41X-10Q is an important component in pipeline systems. During the water injection operation in the pipeline, a large amount of gas is compressed into the interior of the single-port quick exhaust valve P41X-10Q. At this time, the float inside the valve will descend due to the push of the gas, thereby opening the exhaust passage to allow the gas to be quickly discharged. Once the pipeline is filled with water, the gas gradually decreases, and the float rises under the buoyancy of the water, closing the exhaust passage to prevent water leakage.

The vertical air release valve ZP-1 is a device that plays a key role in pipeline systems. When water begins to fill the pipeline, air inside the pipeline accumulates within the vertical air release valve ZP-1. At this time, the float inside the valve descends with the accumulation of gas, opening the air release port to allow a large amount of air to be expelled quickly. As the water level in the pipeline rises and the gas gradually decreases, the float rises due to buoyancy, closing the air release port. During normal operation of the pipeline, if a small amount of gas is generated, it can also be released through the small hole in the valve, thereby maintaining stable pipeline pressure.

Single Port Exhaust Valve QB1X-10Q

The single-port air release valve QB1X-10Q is an essential component in pipeline systems. When the pipeline system is filled with water, the air accumulated inside can be quickly discharged by the single-port air release valve QB1X-10Q. During normal operation of the pipeline, when it is full of water, it can automatically release small amounts of gas, thereby maintaining the stability of the internal pressure and ensuring the smooth operation of the system.

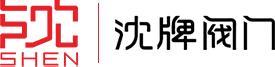

Grooved blind plates are usually made of sturdy metal materials, with a flat shape and edges featuring grooves for connection with matching grooved fittings. Its main characteristic is good sealing performance, effectively preventing the flow of media.

Common materials include stainless steel, cast iron, copper, etc., to meet the requirements of different working environments and media. For example, stainless steel has good corrosion resistance, making it suitable for the transport of corrosive media; cast iron has higher strength and wear resistance, making it suitable for some high-pressure situations.

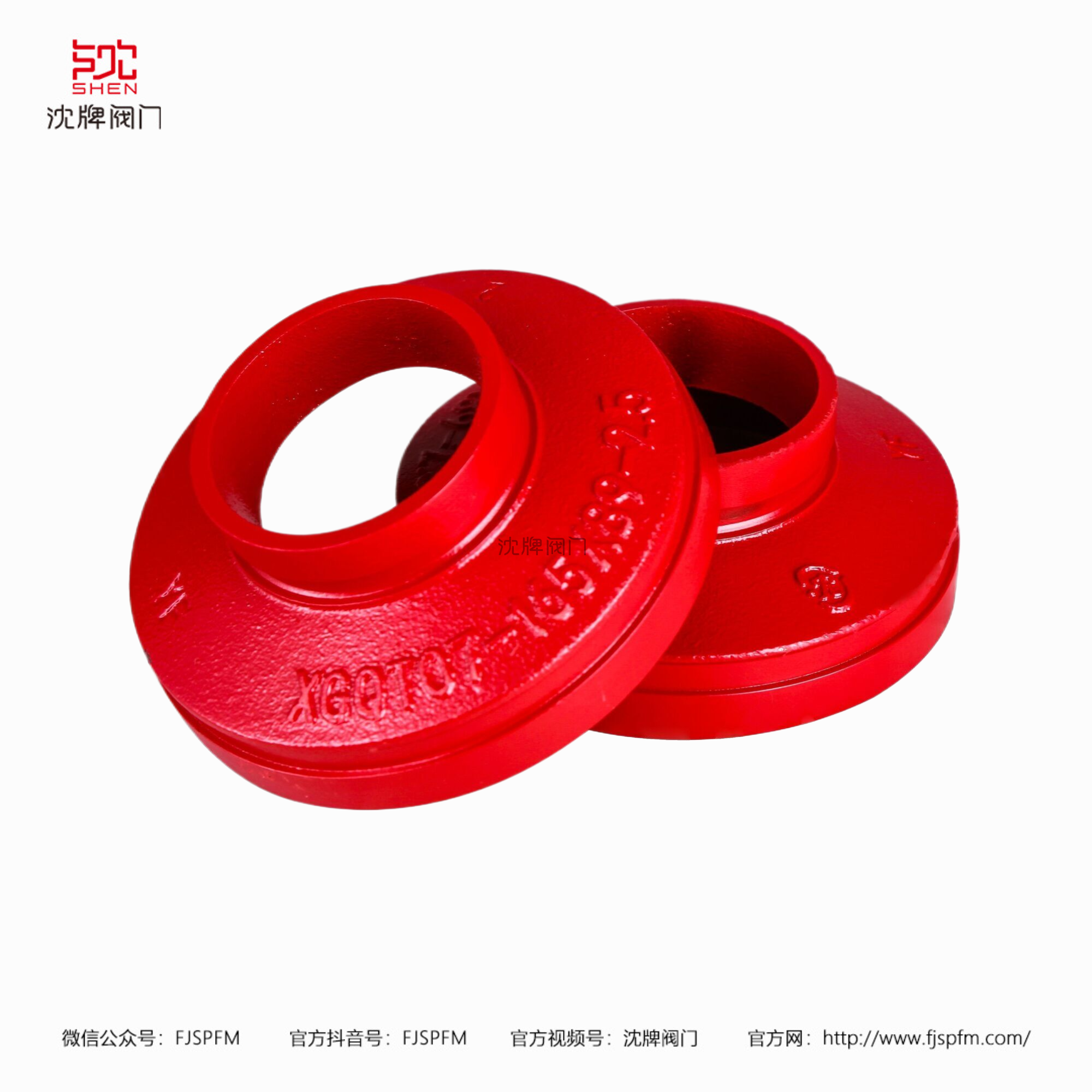

Grooved reducing pipes are usually conical or frustoconical in shape, with different diameters at both ends. They are generally made of high-quality metal materials, such as stainless steel, cast iron, or galvanized steel, to ensure their strength and durability. Grooves are provided at both ends of the pipe for connection with other grooved fittings or pipes.

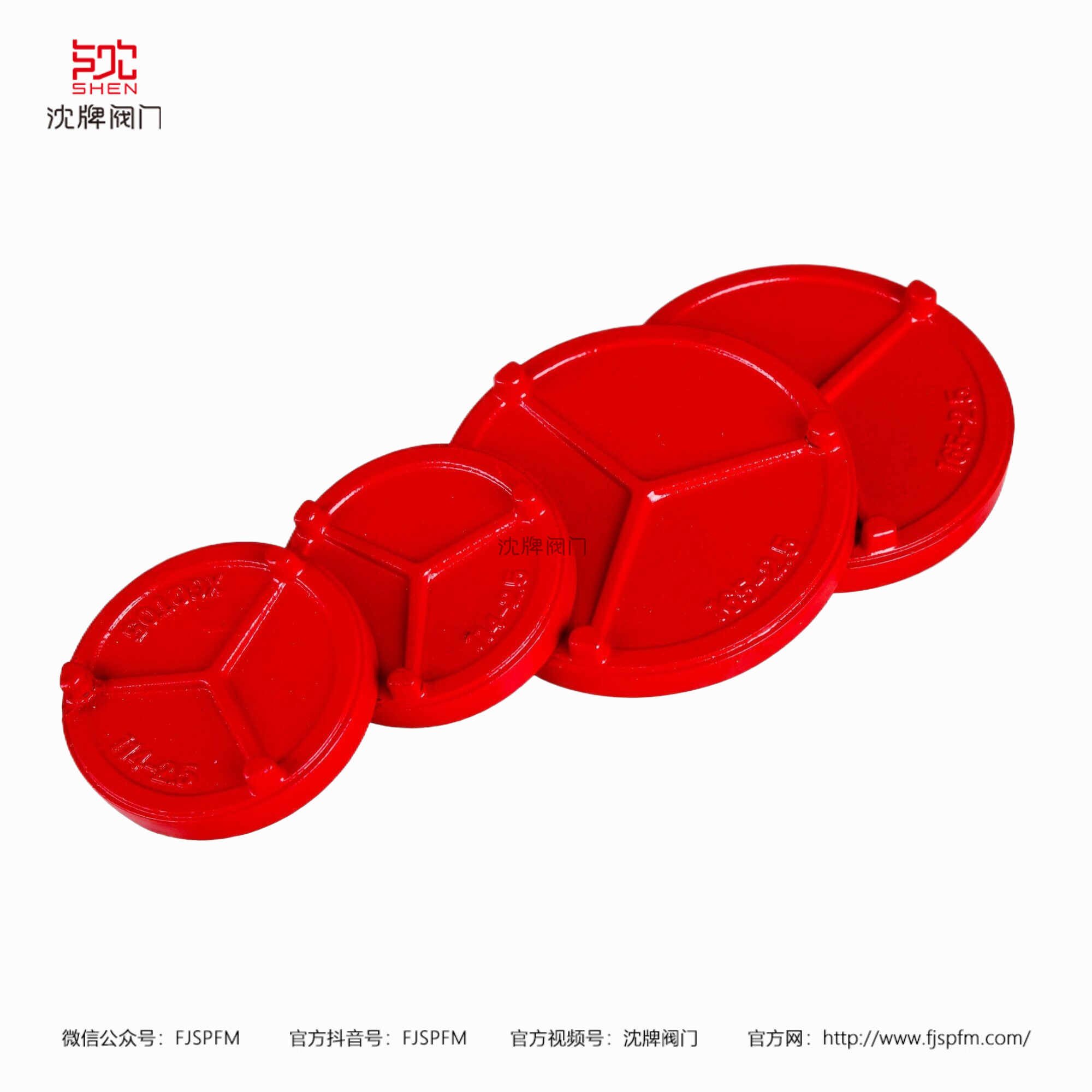

The groove split flange typically consists of two parts: the main body and the sealing gasket. The main body is generally made of high-quality metal materials, such as carbon steel or stainless steel, which have high strength and durability. Its shape is circular, with grooves around the perimeter for connecting with the grooved part of the pipe.

Grooved thread mechanical four-way

The groove mechanical four-way threaded pipe fitting is shaped like a "十" character and has four interfaces. One of the interfaces is threaded for connection to the main pipeline, while the other three interfaces are groove-type for connecting branch pipelines. It is typically made from durable metal materials such as stainless steel or cast steel to ensure its reliability and stability under various working conditions.

Groove flexible pipe clamps are usually composed of a metal shell, rubber sealing rings, and fastening bolts. They have a ring shape and come in various sizes to accommodate pipes of different diameters.

Grooved Mechanical Tee (Threaded Type)

The groove mechanical tee (threaded type) has a 'T' shape and features three interfaces. One interface is threaded for connection to the main pipeline, while the other two interfaces are grooved for connecting branch pipelines. It is typically made from high-strength metal materials, such as stainless steel or cast steel, to ensure its durability and good performance.

Z15X-16P stainless steel internal threaded soft-seal gate valve

The internal threaded dark rod wedge soft-seal gate valve utilizes the compensatory effect of the slight deformation caused by the elastic gate plate under stress to achieve a good sealing effect.

CFZ15X-16P Stainless Steel Internal Thread Magnetic Anti-theft Gate Valve

The magnetic encryption gate valve relies on the force of magnetic force to control the opening and closing of the encryption head. It is a magnetic lock. Generally used for some important, special position and function of the valve, to prevent the valve from being used arbitrarily.

Z15X Internal Thread Soft Sealing Gate Valve

The internal threaded dark rod wedge soft-seal gate valve achieves a good sealing effect by utilizing the compensatory effect of the slight deformation caused by the force on the elastic gate plate.

FZ15X Internal Thread Mechanical Anti-theft Front Valve

The triangular lock gate valve relies on the force of a special triangular key that fits the triangular top of the screw rod to control the opening and closing of the valve. It is a type of triangular lock.

CFZ15X Internal Thread Magnetic Anti-theft Valve

Magnetic encryption gate valves rely on magnetic force to control the opening and closing of the encryption head inside. It is a type of magnetic lock. Generally used on important, special position, and functional valves to prevent arbitrary switching of the valve.

Z81X-16P stainless steel grooved exposed soft-seal gate valve

Grooved (clamp) connection valves have the advantages of quick, easy, safe, and reliable installation, are not limited by installation site, facilitate maintenance of pipelines and valves, provide vibration and sound insulation, and can overcome deviations caused by different axes in pipeline connections within a certain angle range, addressing issues such as thermal expansion and contraction due to temperature differences.