Products

SP-ZSTMB horizontal installation water curtain nozzle

The SP-ZSTMB water curtain nozzle is a high-performance, well-designed firefighting device specifically created to provide efficient fire separation and protection functions.

SP-ZSTWB Centrifugal Water Mist Nozzle A/B

The ZSTWB water curtain nozzle is a high-quality fire protection device meticulously developed to provide efficient and reliable fire separation and cooling protection for various locations.

ZSTMA Vertical Installation Water Curtain Nozzle

The ZSTM series water curtain nozzles are a meticulously designed and high-performance fire protection device, aimed at providing efficient fire separation and cooling protection for various locations. Whether in industrial plants, commercial buildings, cultural venues, or public transportation hubs, the ZSTM series water curtain nozzles play a crucial role in ensuring the safety of people and property.

Foam nozzles are advanced devices specifically designed for firefighting, providing a reliable and effective solution for fire safety. Foam nozzles can spray fine and rich foam, which has excellent coverage and firefighting capabilities. The foam can quickly form a protective layer that isolates oxygen on the burning surface, effectively suppressing the spread of flames and rapidly lowering the temperature of the burning area, thus quickly extinguishing the fire.

The ESFR series quick response sprinkler is an advanced firefighting device designed for efficient fire extinguishing. It features an extremely rapid response mechanism that can quickly activate in the early stages of a fire, spraying water to extinguish flames and significantly reduce damage caused by the fire. For example, in some warehouses and high-pile storage areas, the ESFR sprinkler can respond swiftly as soon as flames ignite, effectively curbing the spread of the fire.

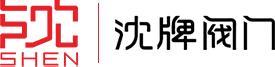

Electronic descaling devices are an innovative water treatment equipment designed to solve scaling problems in pipes and equipment. These devices use advanced electronic technology to release electromagnetic waves of specific frequencies into the water, altering the physical properties of scaling ions such as calcium and magnesium, making it difficult for them to form hard scale. Instead, they exist in a loose particle form in the water and are flushed out of the system with the water flow.

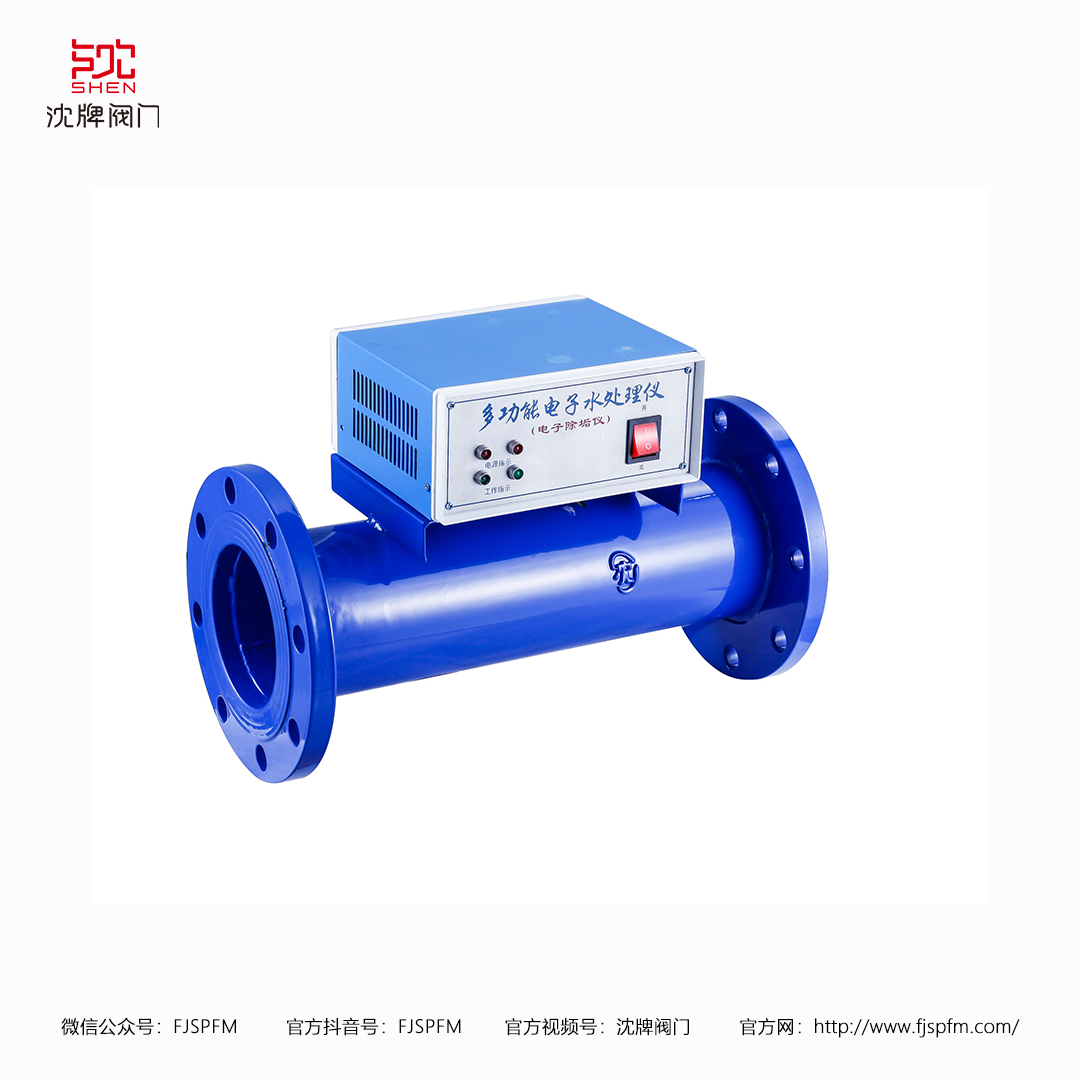

Micro-resistance slow-closing check valve SP-HH44X

The micro-resistance slow-closing check valve is a valve device that plays an important role in pipeline systems. Through its unique structural design, it can slowly close when the medium flows back, effectively reducing the occurrence of water hammer. The internal buffering device can control the closing speed of the valve, thereby reducing pressure fluctuations in the pipeline system.

Telescopic straight through filter SFZ-PN16

The expansion flange straight-through filter is a device that plays an important role in filtering and connecting within a piping system. When fluid passes through the expansion flange straight-through filter, impurities are intercepted by the filter elements inside the filter cartridge, while the pure fluid flows through smoothly. Regular maintenance and cleaning of the filter can involve replacing or cleaning the filter elements to maintain its good filtering performance.

The ARVX threaded exhaust valve is a high-performance exhaust device specifically designed for pipeline systems. With its exquisite craftsmanship and reliable performance, it provides effective exhaust solutions for various pipeline systems. The ARVX threaded exhaust valve features a unique mechanical structure. When the pipeline system begins to fill with water or operate, gas accumulates at the top of the valve, causing the water level inside the valve to drop. At this point, the float descends with the water level, driving the lever to open the exhaust port, allowing gas to be rapidly expelled. As the gas decreases, the water level rises, the float ascends, and the exhaust port closes. When negative pressure occurs within the pipeline, the vacuum-breaking device inside the valve automatically opens, drawing in outside air to protect the pipeline from negative pressure damage.

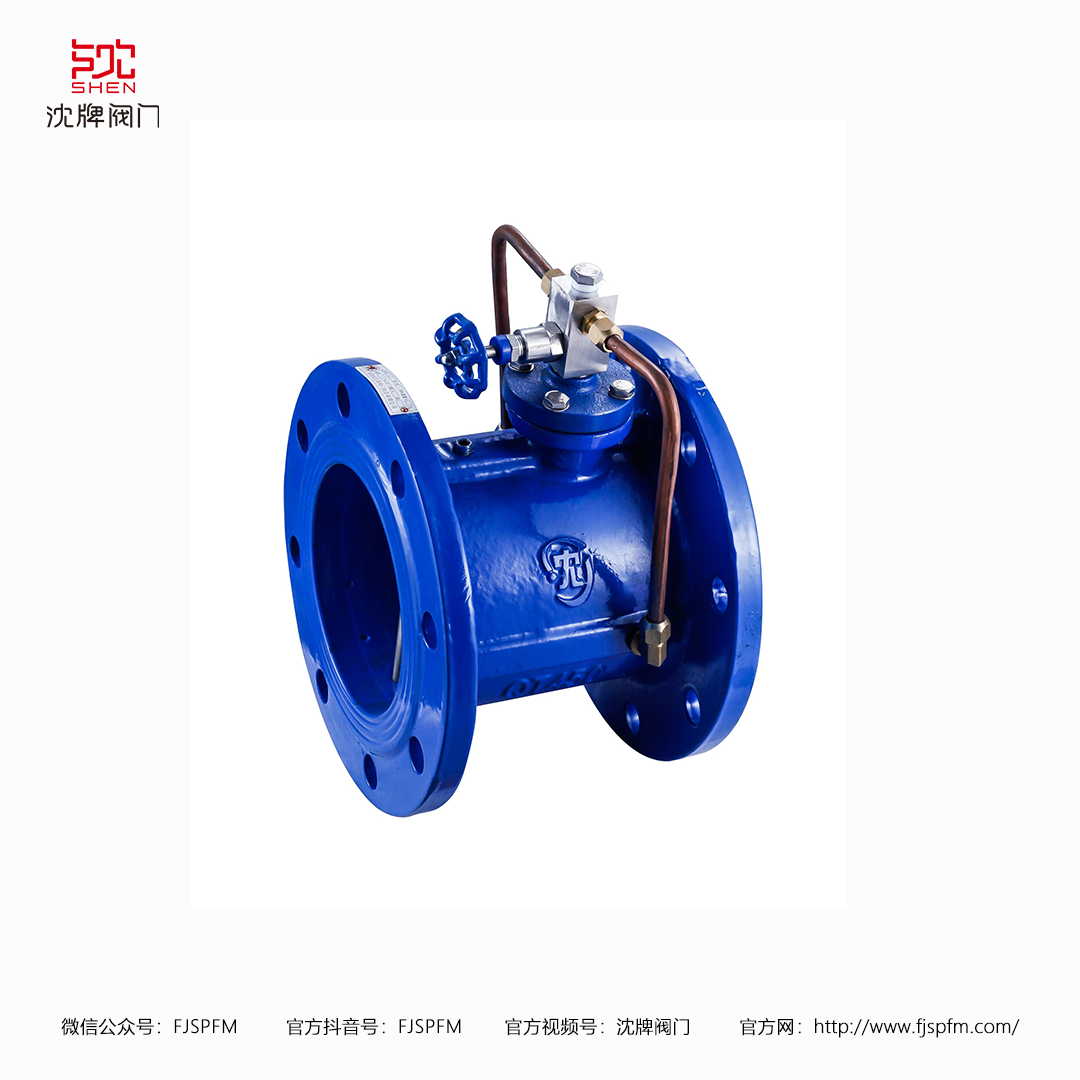

New Composite Exhaust Valve FSP-16Q

The new type compound exhaust valve FSP-16Q is a well-designed and excellent-performance exhaust equipment, aiming to provide efficient and stable exhaust solutions for various pipeline systems. The FSP-16Q compound exhaust valve is mainly composed of two parts: the float ball and the cylinder. When water is injected into the pipeline system, a large amount of gas gathers in the upper part of the valve, the water level in the valve drops, the float ball drops along with the water level, and opens the exhaust port to discharge the gas. As the gas in the pipeline decreases, the water level gradually rises, and the float ball also rises, blocking the exhaust port. When negative pressure occurs in the pipeline, the water level in the valve drops, and the outside air enters the valve through the suction port to prevent the pipeline from being damaged due to negative pressure.

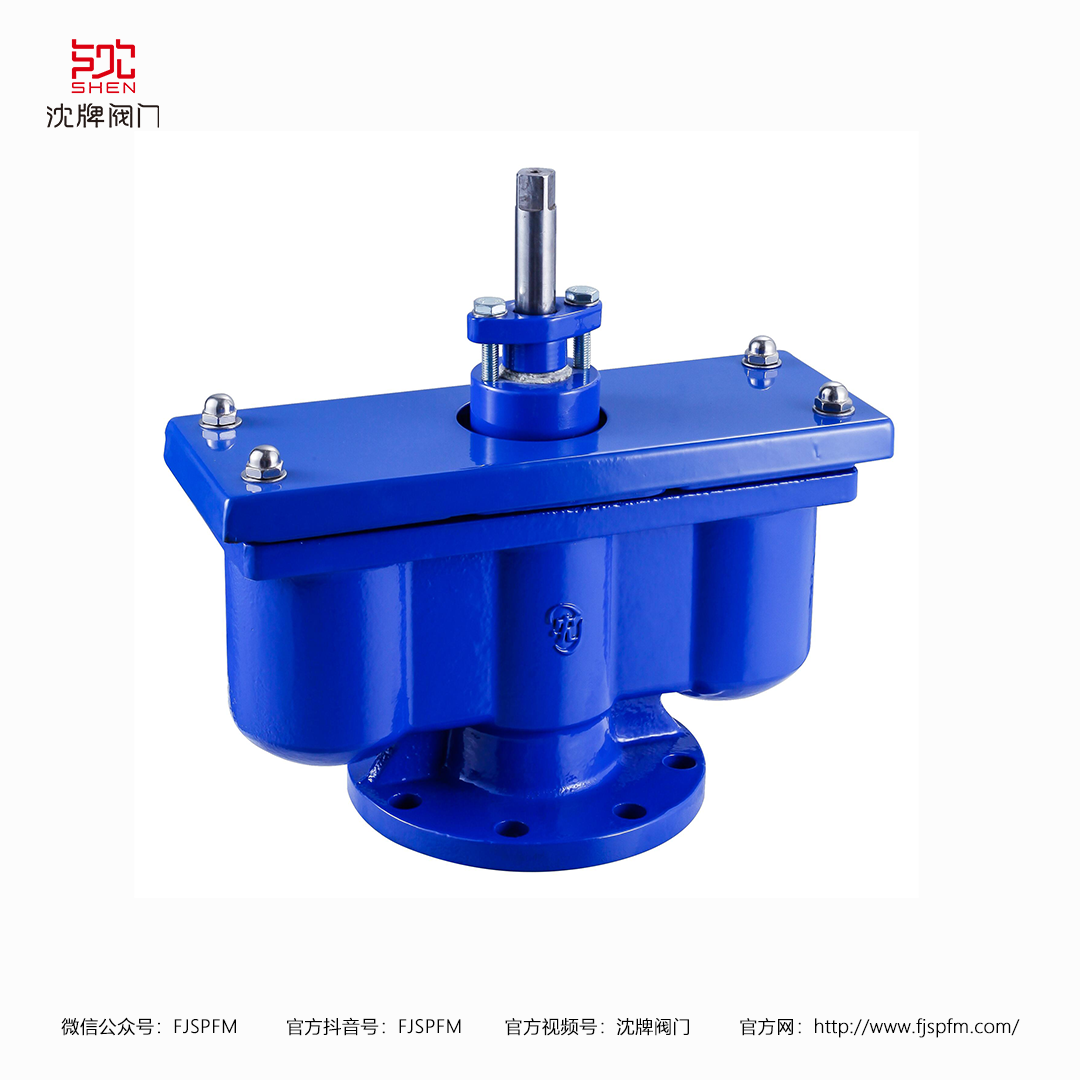

Dual Port Exhaust Valve QB2-16Q

The double-port exhaust valve QB2-16Q is a valve device that plays an important role in pipeline systems. Through its special internal structure, it can quickly discharge a large amount of air from the pipeline when water is injected into the system, and after the pipeline is filled with water, it can effectively expel trace gases to ensure the normal operation of the pipeline system.

The horizontal exhaust valve FQ-2 is an important device in pipeline systems. During the water injection process, air in the pipeline accumulates at the horizontal exhaust valve FQ-2. The internal mechanism of the valve responds to the presence of gas, quickly opening the exhaust passage to allow air to be rapidly discharged. As water injection continues, the water level rises and gas decreases. When the pipeline is filled with water and gas is mostly evacuated, the components inside the valve will act to close the exhaust passage, ensuring the sealing of the pipeline.

New composite exhaust valve FGP41X-16Q

The new composite exhaust valve FGP41X-16Q is an innovative key device in pipeline systems. When the pipeline is initially filled with water, a large amount of air quickly gathers at the new composite exhaust valve FGP41X-16Q. At this time, the large-diameter exhaust passage in the valve rapidly opens, allowing for the quick discharge of air. As the water filling continues, the water level gradually rises, the amount of gas decreases but the pressure increases, at which point the small-diameter exhaust passage comes into play, expelling the remaining trace gases. When the pipeline is full of water and the gas is mostly discharged, the float rises due to the buoyancy of the water, accurately closing the exhaust port and effectively preventing water leakage.

Composite Exhaust Valve CARX-16Q

The compound exhaust valve CARX-16Q is a key component with excellent performance in the pipeline system. During the water injection stage of the pipeline, a large amount of gas rushes into the compound exhaust valve CARX-16Q. At this time, the large-hole exhaust port inside the valve quickly opens to achieve rapid exhaust. As the water level in the pipeline rises, the gas pressure increases, and the small-hole exhaust port starts to work, discharging trace amounts of gas. When the pipeline is filled with water and the gas is basically exhausted, the float rises under the buoyancy force, closing the exhaust port to prevent water leakage.

The KP quick exhaust valve is an important device with significant performance advantages in pipeline systems. When the pipeline system begins to fill with water, a large amount of gas quickly accumulates inside the KP quick exhaust valve. The special structure inside the valve allows the internal components to sensitively detect gas pressure, enabling the rapid opening of the exhaust channel for quick gas release. As the filling process continues, the water level in the pipeline rises, the amount of gas decreases, and pressure changes cause the internal components of the exhaust valve to act, gradually closing the exhaust channel to ensure that water does not leak.