Products

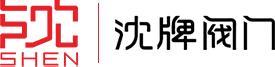

Micro-resistance slow-closing check valve SP-HH44X

The micro-resistance slow-closing check valve is a valve device that plays an important role in pipeline systems. Through its unique structural design, it can slowly close when the medium flows back, effectively reducing the occurrence of water hammer. The internal buffering device can control the closing speed of the valve, thereby reducing pressure fluctuations in the pipeline system.

HQ41X Flanged Ball Check Valve

The HQ41X sliding ball check valve uses a rubber-coated rolling ball as the valve foot, which can roll up and down on the integral sliding track of the valve body under the action of gravity, thereby opening or closing the valve. It has good sealing performance, silent closing, and does not produce water hammer.

The valve consists of components such as the valve body, valve seat, flow guide, valve disc, bearing, and spring. The internal flow path is designed with a streamlined shape, resulting in low pressure loss. The valve disc has a very short opening and closing stroke, allowing for quick closure when the pump is stopped, preventing a significant water hammer sound and creating a silent effect. This valve is mainly used in water supply, drainage, fire protection, and HVAC systems, and can be installed at the pump outlet to prevent backflow of the medium and damage to the pump from water hammer.

The rubber flap check valve is mainly used at the pump outlet of drainage systems, petrochemical, metallurgy, and other industrial sectors to prevent backflow of the medium. This valve can also be installed on the bypass pipe of the inlet and outlet water pipes of a reservoir to prevent backflow of pool water that could damage the pump. Due to the inclined design of the sealing ring, the closing time is short, which can reduce water hammer pressure. The valve flap is made of oil-resistant nitrile rubber and steel plate pressed at high temperatures, making it resistant to impact and providing good sealing performance. The product has a simple structure, making maintenance, repair, and transportation very convenient, with reliable sealing performance achieving bi-directional sealing with zero leakage.

H81X Groove Silencing Check Valve

A silent check valve refers to a valve that automatically opens and closes its disc based on the flow of the medium itself, used to prevent backflow of the medium. It is also known as a non-return valve, one-way valve, silent check valve, backflow valve, and back pressure valve. The check valve is a type of automatic valve, and its main functions are to prevent backflow of the medium, prevent pumps and driving motors from reversing, and to prevent the release of the medium in containers. Check valves can also be used in pipelines that supply auxiliary systems where the pressure may exceed the system pressure.

The swing check valve mainly consists of three main components: the valve body, the valve cover, and the rubber flap. The swing check valve opens or closes automatically based on the flow of fluid and pressure to prevent backflow. It is suitable for horizontal installation in water supply and drainage systems and can be installed at the outlet of a pump to prevent backflow and water hammer damage to the pump.

The groove ball check valve uses a rubber-coated rolling ball as the valve foot, which can roll up and down on the integral slide of the valve body under the action of the medium, thereby opening or closing the valve. It has good sealing performance, silent closing, and does not produce water hammer.

H41X flange silencer check valve

This valve is installed on the outlet pipeline of the pump to prevent water hammer from impacting the pump's reverse rotation and to protect the safety of the pipeline when the pump is shut down. This valve is small in size, lightweight, easy to install and maintain, has a guiding device, closes flexibly, provides linear sealing, and has excellent check valve effects, effectively eliminating closing noise. It is suitable for water supply and drainage, fire protection, HVAC, and other related pump outlets to prevent backflow of the medium and damage from water hammer to the pump and pipeline.

H84X groove rubber flap check valve

The rubber flap check valve consists of a valve body, valve cover, and valve flap, and is mainly used in the pipeline outlet of drainage systems, petroleum, chemical, and other industrial sectors to prevent backflow of media. Due to the inclined design of the sealing ring, the closing time is short, which can reduce water hammer pressure.

H71X Flanged Silent Check Valve

The H71X-10/16 wafer-type silent check valve is mainly installed at the outlet of the water pump. This valve consists of a valve body, valve seat, valve disc, valve rod, spring, and other components. When the pressure at the inlet is greater than the outlet pressure and the spring pressure, the valve opens; when the pump stops, under the action of the spring's pre-tension, the valve disc quickly closes due to the drop in water head, and the very short opening of the valve disc effectively prevents the formation of water hammer and eliminates noise. This valve is currently one of the most commonly used types of check valves.