Products

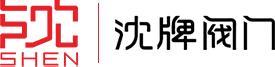

Electronic descaling devices are an innovative water treatment equipment designed to solve scaling problems in pipes and equipment. These devices use advanced electronic technology to release electromagnetic waves of specific frequencies into the water, altering the physical properties of scaling ions such as calcium and magnesium, making it difficult for them to form hard scale. Instead, they exist in a loose particle form in the water and are flushed out of the system with the water flow.

The ARVX threaded exhaust valve is a high-performance exhaust device specifically designed for pipeline systems. With its exquisite craftsmanship and reliable performance, it provides effective exhaust solutions for various pipeline systems. The ARVX threaded exhaust valve features a unique mechanical structure. When the pipeline system begins to fill with water or operate, gas accumulates at the top of the valve, causing the water level inside the valve to drop. At this point, the float descends with the water level, driving the lever to open the exhaust port, allowing gas to be rapidly expelled. As the gas decreases, the water level rises, the float ascends, and the exhaust port closes. When negative pressure occurs within the pipeline, the vacuum-breaking device inside the valve automatically opens, drawing in outside air to protect the pipeline from negative pressure damage.

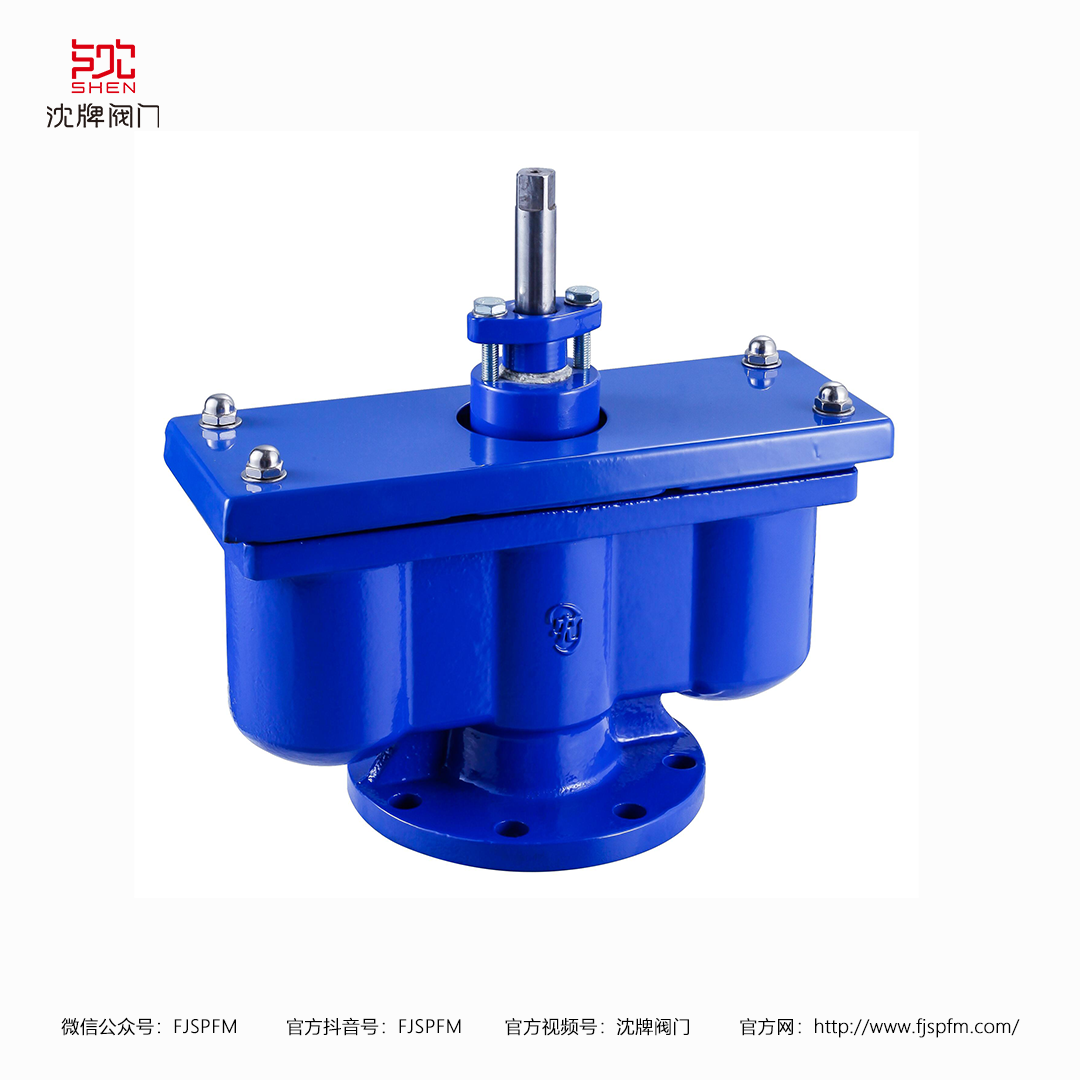

New Composite Exhaust Valve FSP-16Q

The new type compound exhaust valve FSP-16Q is a well-designed and excellent-performance exhaust equipment, aiming to provide efficient and stable exhaust solutions for various pipeline systems. The FSP-16Q compound exhaust valve is mainly composed of two parts: the float ball and the cylinder. When water is injected into the pipeline system, a large amount of gas gathers in the upper part of the valve, the water level in the valve drops, the float ball drops along with the water level, and opens the exhaust port to discharge the gas. As the gas in the pipeline decreases, the water level gradually rises, and the float ball also rises, blocking the exhaust port. When negative pressure occurs in the pipeline, the water level in the valve drops, and the outside air enters the valve through the suction port to prevent the pipeline from being damaged due to negative pressure.

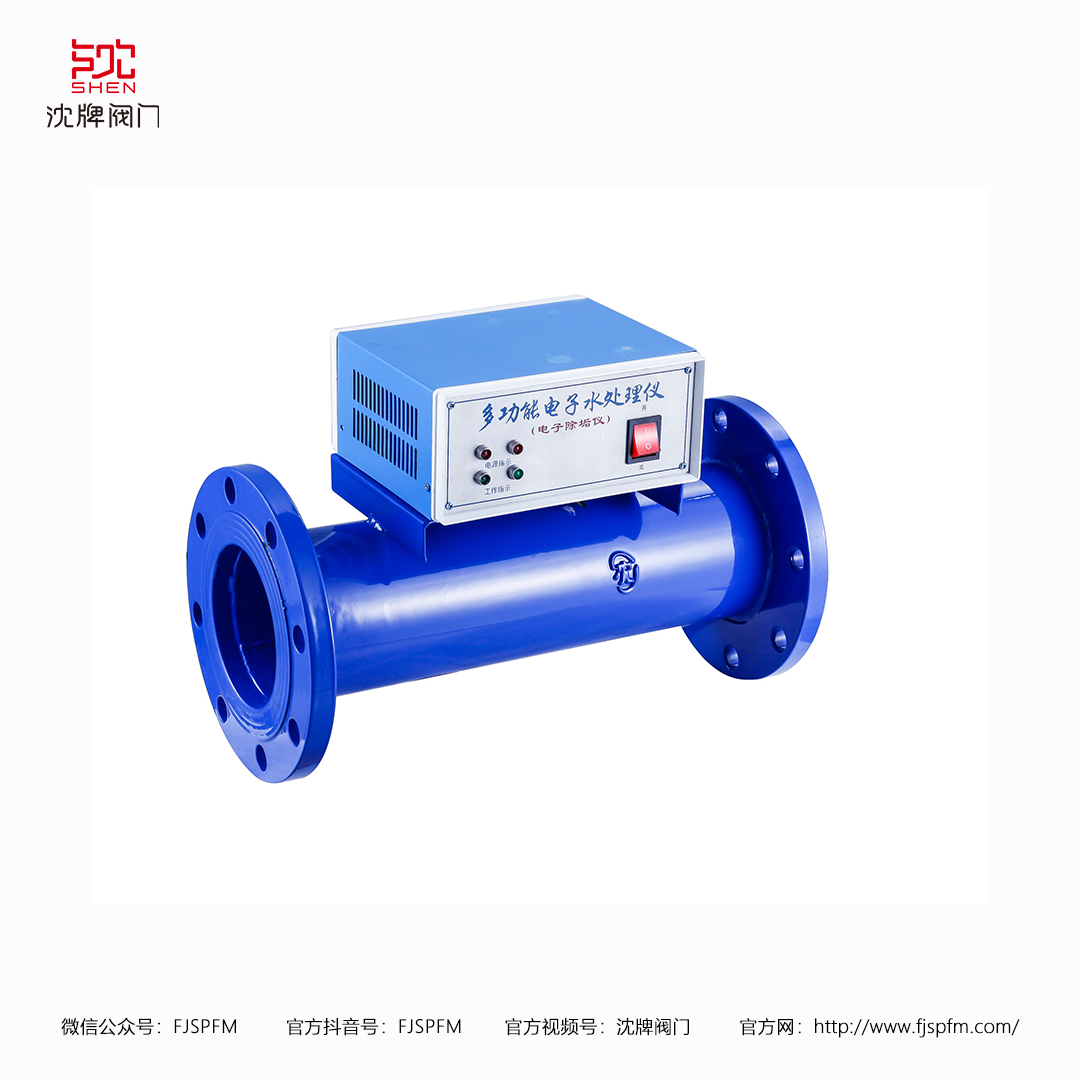

Dual Port Exhaust Valve QB2-16Q

The double-port exhaust valve QB2-16Q is a valve device that plays an important role in pipeline systems. Through its special internal structure, it can quickly discharge a large amount of air from the pipeline when water is injected into the system, and after the pipeline is filled with water, it can effectively expel trace gases to ensure the normal operation of the pipeline system.

The horizontal exhaust valve FQ-2 is an important device in pipeline systems. During the water injection process, air in the pipeline accumulates at the horizontal exhaust valve FQ-2. The internal mechanism of the valve responds to the presence of gas, quickly opening the exhaust passage to allow air to be rapidly discharged. As water injection continues, the water level rises and gas decreases. When the pipeline is filled with water and gas is mostly evacuated, the components inside the valve will act to close the exhaust passage, ensuring the sealing of the pipeline.

New composite exhaust valve FGP41X-16Q

The new composite exhaust valve FGP41X-16Q is an innovative key device in pipeline systems. When the pipeline is initially filled with water, a large amount of air quickly gathers at the new composite exhaust valve FGP41X-16Q. At this time, the large-diameter exhaust passage in the valve rapidly opens, allowing for the quick discharge of air. As the water filling continues, the water level gradually rises, the amount of gas decreases but the pressure increases, at which point the small-diameter exhaust passage comes into play, expelling the remaining trace gases. When the pipeline is full of water and the gas is mostly discharged, the float rises due to the buoyancy of the water, accurately closing the exhaust port and effectively preventing water leakage.

Composite Exhaust Valve CARX-16Q

The compound exhaust valve CARX-16Q is a key component with excellent performance in the pipeline system. During the water injection stage of the pipeline, a large amount of gas rushes into the compound exhaust valve CARX-16Q. At this time, the large-hole exhaust port inside the valve quickly opens to achieve rapid exhaust. As the water level in the pipeline rises, the gas pressure increases, and the small-hole exhaust port starts to work, discharging trace amounts of gas. When the pipeline is filled with water and the gas is basically exhausted, the float rises under the buoyancy force, closing the exhaust port to prevent water leakage.

The KP quick exhaust valve is an important device with significant performance advantages in pipeline systems. When the pipeline system begins to fill with water, a large amount of gas quickly accumulates inside the KP quick exhaust valve. The special structure inside the valve allows the internal components to sensitively detect gas pressure, enabling the rapid opening of the exhaust channel for quick gas release. As the filling process continues, the water level in the pipeline rises, the amount of gas decreases, and pressure changes cause the internal components of the exhaust valve to act, gradually closing the exhaust channel to ensure that water does not leak.

Single Port Quick Exhaust Valve P41X-10Q

The single-port quick exhaust valve P41X-10Q is an important component in pipeline systems. During the water injection operation in the pipeline, a large amount of gas is compressed into the interior of the single-port quick exhaust valve P41X-10Q. At this time, the float inside the valve will descend due to the push of the gas, thereby opening the exhaust passage to allow the gas to be quickly discharged. Once the pipeline is filled with water, the gas gradually decreases, and the float rises under the buoyancy of the water, closing the exhaust passage to prevent water leakage.

The vertical air release valve ZP-1 is a device that plays a key role in pipeline systems. When water begins to fill the pipeline, air inside the pipeline accumulates within the vertical air release valve ZP-1. At this time, the float inside the valve descends with the accumulation of gas, opening the air release port to allow a large amount of air to be expelled quickly. As the water level in the pipeline rises and the gas gradually decreases, the float rises due to buoyancy, closing the air release port. During normal operation of the pipeline, if a small amount of gas is generated, it can also be released through the small hole in the valve, thereby maintaining stable pipeline pressure.

Single Port Exhaust Valve QB1X-10Q

The single-port air release valve QB1X-10Q is an essential component in pipeline systems. When the pipeline system is filled with water, the air accumulated inside can be quickly discharged by the single-port air release valve QB1X-10Q. During normal operation of the pipeline, when it is full of water, it can automatically release small amounts of gas, thereby maintaining the stability of the internal pressure and ensuring the smooth operation of the system.

SGA9000X-16P Piston Water Hammer Absorber

The SGA9000X piston-type water hammer absorber is a device used to eliminate water hammer shock waves caused by various reasons in pipelines, protecting pipes and equipment from damage. It utilizes the expansion and contraction of air in the upper chamber of the piston to buffer sudden shock waves, thereby alleviating their intensity and minimizing equipment damage caused by massive water hammer forces. This device has a simple structure, high-quality materials, and a long service life.

A swirl preventer is a special pipe fitting used to prevent swirling in a tank (pool) when transporting liquids and to prevent air from entering the pipeline. Its function is to be installed at the inlet of the water pump suction pipe of the tank (pool) to eliminate swirling within the tank (pool), ensuring that the water pump can start at full power and operate normally, avoiding cavitation caused by air entering the pump, and allowing the liquid level in the tank (pool) to drop to a lower level to ensure maximum flow delivery.

SP45F Digital Locking Balancing Valve

This valve is a type of balancing valve, suitable for various liquid pipeline systems, and is a relatively ideal new energy-saving valve. The valve is equipped with a digital display with scales, allowing for intuitive adjustment to any position, and can be locked. This valve is mainly used in heating pipeline systems for industrial and civil buildings. Currently, there are issues of hydraulic imbalance in some pipeline systems, and the balancing valve provides a means to solve this problem, allowing for accurate adjustment of pressure drop and flow rate to improve the flow conditions of liquids in the pipeline system, achieving liquid balance and energy savings. In the renovation of dual-pipe network projects, the application of this valve can still save energy and achieve good results.

The measurement principle of electromagnetic flowmeters is based on Faraday's law of electromagnetic induction. The main components of the sensor include: measuring tube, electrodes, excitation coil, iron core, and magnetic shell. Electromagnetic flowmeters are primarily used to measure the volumetric flow of conductive liquids and slurries in closed pipelines, including highly corrosive liquids such as acids, bases, and salts. Electromagnetic flowmeters are widely used in petrochemical, steel metallurgy, water supply and drainage, hydraulic irrigation, water treatment, environmental sewage total control, papermaking, pharmaceuticals, food, and other industrial and agricultural applications.

Y43X proportional pressure reducing valve

The Y43X proportional pressure reducing valve utilizes the pressure difference generated by the different cross-sectional areas at both ends of the internal piston to change the pressure after the valve, achieving the purpose of pressure reduction. It has accurate proportions, stable operation, long service life, and can withstand high temperatures. It can reduce both dynamic and static pressure and can be installed horizontally or vertically.