Products

Grooved 90° Elbow

Classification:

Keyword:

SHENPAI

Product accessories:

The grooved 90-degree elbow is a pipe fitting with a 90-degree bending angle. Its two ends usually have grooves to facilitate connection with other grooved pipe fittings and pipes. It is usually manufactured from high-quality metal materials, such as cast iron, stainless steel or galvanized steel.

InquiryProduct Details/Product Details

1. Introduction

The grooved 90-degree elbow is an essential component in pipeline systems, playing a key role in changing the direction of the pipeline.

2. Product Overview

The grooved 90-degree elbow is a fitting with a 90-degree bend, typically featuring grooves at both ends for connection with other grooved fittings and pipes. It is usually made from high-quality metal materials such as cast iron, stainless steel, or galvanized steel.

3. Working Principle

The grooved 90-degree elbow guides fluid to make a 90-degree turn in the pipeline through its unique curved shape. Its smooth internal curve design helps reduce flow resistance, ensuring smooth fluid transmission.

4. Features and Advantages

- Easy Installation

Using a grooved connection method eliminates the need for complex welding or threading, significantly shortening installation time and reducing construction difficulty.

For example, in the pipeline installation projects of large commercial buildings, using grooved 90-degree elbows can quickly complete adjustments to the pipeline layout. - Reliable Sealing

Equipped with high-quality rubber sealing rings, it ensures that there are no leakage issues at the connection points, enhancing the safety and stability of the pipeline system.

In water supply pipeline systems, good sealing can prevent water resource waste and potential safety hazards. - Sturdy Structure

Carefully designed and manufactured to withstand high pressure and impact, suitable for various harsh working environments.

In industrial pipeline systems, it often encounters impacts from high pressure and high-speed fluids, and the grooved 90-degree elbow can operate stably. - Good Corrosion Resistance

Through surface treatment and the selection of corrosion-resistant materials, its service life is extended, and maintenance costs are reduced.

In corrosive environments such as chemical industries, it can still maintain good performance.

5. Application Fields

- Building Water Supply and Drainage

Widely used in the water supply and drainage pipeline systems of buildings such as residences, office buildings, and shopping malls to change the direction of the pipelines. - Fire Protection Engineering

In fire protection pipeline networks, it ensures that fire water can smoothly reach every corner, providing safety for fire protection. - HVAC

Used for connecting pipes in air conditioning and ventilation systems, allowing air or hot and cold water to flow according to design requirements. - Oil and Gas

In oil and gas transportation pipelines, it adapts to complex terrain and changes in pipeline direction.

6. Selection and Usage Considerations

- Material Selection

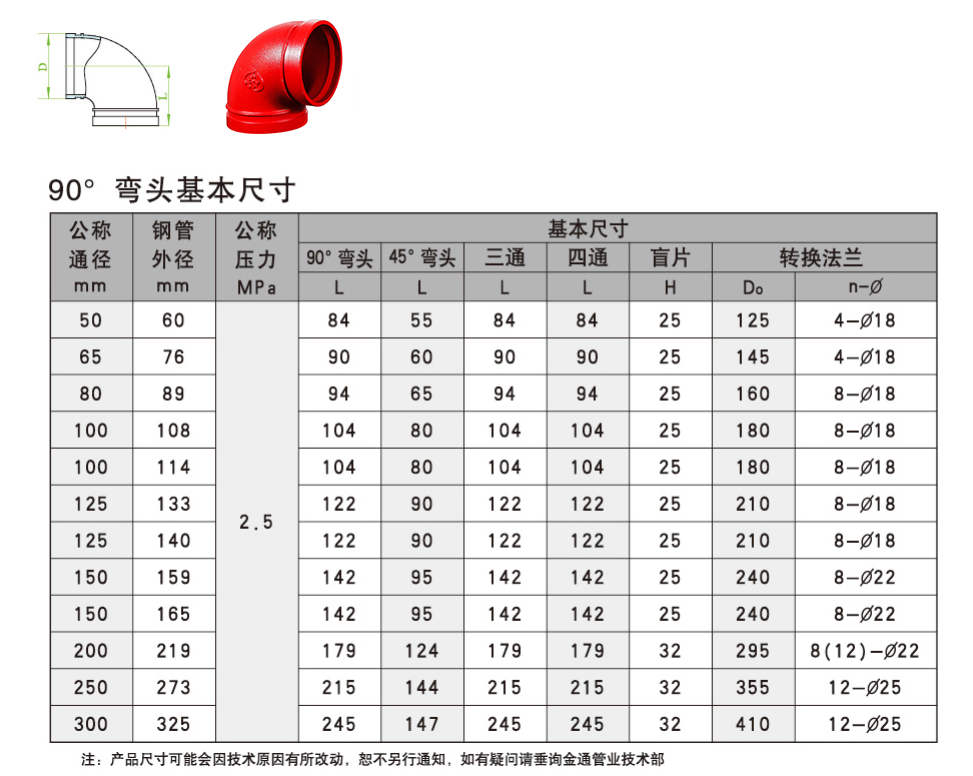

Choose appropriate materials based on the nature, temperature, and pressure of the conveyed medium, such as stainless steel for corrosive media and cast iron for general conditions. - Size Matching

Ensure that the size of the elbow matches the diameter and wall thickness of the pipeline to avoid loose connections. - Installation Specifications

Strictly follow the installation instructions to ensure the processing accuracy of the grooves and the correct installation of the sealing rings.

In summary, the grooved 90-degree elbow plays an important role in pipeline systems with its unique performance and advantages. In practical applications, reasonable selection and correct installation can fully exert its function, ensuring the safe and efficient operation of the pipeline system.

Related Products/Related Products

Solutions for your industry, ready for your choices